Solar Power Factory: A Comprehensive Guide to Manufacturing and Applications

By admin

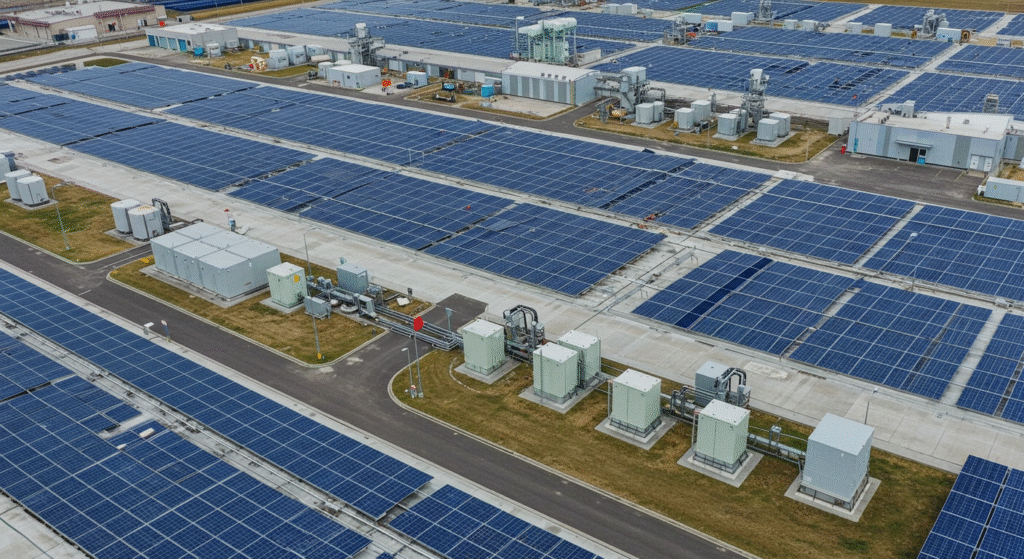

A solar power factory is a specialized facility dedicated to manufacturing components for solar energy systems, such as photovoltaic (PV) panels, inverters, batteries, and mounting structures. These factories play a critical role in the renewable energy ecosystem, producing the technology that harnesses sunlight to generate clean electricity. Solar power factories are at the forefront of sustainable innovation, supporting global efforts to reduce carbon emissions and transition to renewable energy. This guide explores the operations, components, processes, applications, and benefits of solar power factories, emphasizing their importance in advancing solar energy adoption.

Solar power factories produce a range of products, from silicon solar cells to complete PV modules, often incorporating advanced automation and eco-friendly practices. With the global demand for solar energy surging—evidenced by posts on X highlighting new factories and capacity expansions—these facilities are expanding rapidly, creating jobs and driving economic growth. For innovative solar energy solutions, including components produced in solar power factories, visit Power Solution.

Components of Solar Power Factory Operations

Solar power factories are complex operations that integrate multiple processes to produce high-quality solar components. Understanding the key elements of these facilities provides insight into their efficiency and output. Below is an overview of the primary components involved:

Raw Material Processing

Solar power factories begin with raw materials like polysilicon, the foundation of most PV panels. Polysilicon is refined into high-purity silicon ingots, which are then sliced into thin wafers. This process requires precision equipment to ensure quality.

- Function: Converts raw materials into usable forms for solar cell production.

- Key Features: High-purity output, energy-intensive processes, and strict quality control.

Solar Cell Manufacturing

Wafers are transformed into solar cells through doping (adding phosphorus or boron) and coating with anti-reflective layers. Solar power factories use automated systems to create n-type or p-type cells, which determine panel efficiency.

- Function: Produces the core electricity-generating component of PV panels.

- Key Features: Cleanroom environments, precision doping, and efficiency optimization.

Module Assembly

Solar cells are interconnected and encapsulated in a protective module. This involves soldering cells, laminating them with glass and polymer layers, and framing the module. Solar power factories ensure modules are durable and weather-resistant.

- Function: Creates complete PV panels ready for installation.

- Key Features: Automated assembly lines, waterproof sealing, and rigorous testing.

Power Electronics Production

Inverters and power optimizers, which convert direct current (DC) to alternating current (AC), are manufactured in specialized sections. These components are critical for integrating solar energy into electrical grids.

- Function: Enables compatibility with grid and home systems.

- Key Features: Circuit board assembly, high reliability, and smart technology integration.

Mounting and Tracking Systems

Solar power factories produce racking systems and trackers to support and position PV panels. These are typically made from steel or aluminum, designed for durability and corrosion resistance.

- Function: Ensures optimal panel placement and sunlight capture.

- Key Features: Customizable designs, weather resistance, and tracking mechanisms.

Quality Control and Testing

Every component undergoes rigorous testing to meet industry standards. Solar power factories use automated systems to check for defects, efficiency, and durability under various conditions.

- Function: Guarantees product reliability and performance. “‘Key Features**: Advanced diagnostics, environmental simulation, and certification compliance.

Types of Solar Power Factory Outputs

Solar power factories produce a variety of products tailored to different applications. The table below summarizes the main outputs, their features, and ideal uses:

| Output | Description | Best Use Case | Key Features |

|---|---|---|---|

| Monocrystalline PV Panels | Made from single-crystal silicon, offering high efficiency. | Residential, commercial rooftops | High efficiency, sleek design, long lifespan |

| Polycrystalline PV Panels | Made from multi-crystal silicon, more cost-effective. | Utility-scale solar farms | Balanced efficiency, scalable production |

| Thin-Film PV Panels | Uses materials like cadmium telluride for lightweight panels. | Large-scale projects, flexible applications | Lightweight, lower efficiency, easy to produce |

| Solar Inverters | Converts DC to AC, available in string or microinverter formats. | All solar installations | High conversion efficiency, smart monitoring |

| Solar Batteries | Stores energy for off-grid or backup use, often lithium-ion. | Remote areas, residential storage | High capacity, long cycle life, compact design |

| Mounting and Tracking Systems | Supports and positions panels, includes fixed or tracking options. | Utility-scale and commercial projects | Durable materials, sun-tracking capabilities |

These outputs cater to diverse needs, from residential rooftops to massive solar farms, as highlighted in posts on X about new factory openings.

Manufacturing Processes in Solar Power Factories

Solar power factories employ sophisticated processes to ensure high-quality production. Below are the key stages:

Polysilicon Production

Raw silica is refined into polysilicon through energy-intensive processes like the Siemens method. Solar power factories often source polysilicon but may produce it in-house for vertical integration.

- Tip: Ensure supply chain stability for consistent polysilicon quality.

Ingot and Wafer Formation

Polysilicon is melted and shaped into ingots, then sliced into thin wafers. Solar power factories use diamond wire saws for precision cutting to minimize material waste.

- Tip: Optimize wafer thickness for efficiency and cost balance.

Cell Fabrication

Wafers are doped, coated, and etched to create solar cells. Solar power factories use cleanrooms to prevent contamination, ensuring high cell efficiency.

- Tip: Implement automation to reduce human error in cell production.

Module Assembly

Cells are soldered into strings, laminated with glass and polymers, and framed. Solar power factories test modules for waterproofing and durability.

- Tip: Use high-quality encapsulants to enhance module longevity.

Ancillary Component Production

Inverters, batteries, and mounting systems are manufactured in parallel. Solar power factories integrate these components to offer complete solutions.

- Tip: Design modular systems for easy integration in various projects.

Quality Assurance

Solar power factories conduct tests like electroluminescence imaging and thermal cycling to ensure components meet standards like IEC 61215.

- Tip: Invest in automated testing for faster, accurate results.

For reliable solar components produced in advanced factories, explore Power Solution.

Applications of Solar Power Factory Products

Solar power factory products are deployed across various sectors, supporting the global shift to renewable energy. Below are key applications:

Residential Solar Systems

PV panels and inverters power homes, reducing electricity bills. Solar power factory products like monocrystalline panels are popular for their efficiency and aesthetics.

- Example: Qcells panels, produced in U.S. factories, are widely used in residential installations.

Commercial and Industrial Facilities

Factories and warehouses use solar panels to offset high energy costs. Solar power factory outputs, such as large-scale inverters, support these installations.

- Example: A German factory runs entirely on solar power on sunny days, using factory-produced panels.

Utility-Scale Solar Farms

Massive solar parks rely on polycrystalline or thin-film panels for cost-effective power generation. Solar power factories supply trackers to optimize energy capture.

- Example: The Golmud Solar Park in China uses millions of panels from local factories.

Off-Grid and Remote Areas

Solar batteries and panels provide electricity in areas without grid access. Solar power factory products enable reliable power for rural communities.

- Example: Split-type systems from factories power remote African villages.

Specialized Applications

Solar power factory outputs support niche uses, like solar-powered water pumps or street lights, as offered by Power Solution.

- Example: Solar street lights use factory-produced batteries for autonomy.

Benefits of Solar Power Factories

Solar power factories offer significant advantages, driving the renewable energy revolution:

- Sustainability: Produce clean energy technologies, reducing global carbon emissions.

- Economic Growth: Create jobs, as seen in new U.S. factories employing hundreds.

- Energy Independence: Enable countries to reduce reliance on fossil fuel imports.

- Innovation: Drive advancements in efficiency and smart technology, like lightweight panels.

- Scalability: Support projects from small homes to gigawatt-scale solar farms.

- Reliability: Produce durable components with lifespans of 25+ years.

Challenges and Future Trends

Solar power factories face challenges, but innovations are paving the way for growth:

- Supply Chain Constraints: Dependence on imported polysilicon limits domestic production.

- Energy Intensity: Manufacturing processes require significant electricity, often from non-renewable sources.

- Waste Management: Recycling end-of-life panels remains a challenge.

Future trends include:

- Domestic Supply Chains: U.S. factories are expanding to produce cells and wafers locally.

- Advanced Materials: Perovskite cells promise higher efficiencies, with factories scaling production.

- Automation: Robotics enhance precision and reduce costs in solar power factories.

- Sustainability: Factories are adopting solar power for their own operations, as seen in Germany.

Power Solution is contributing to these trends with innovative solar products.

Frequently Asked Questions About Solar Power Factories

What do solar power factories produce?

They manufacture PV panels, inverters, batteries, and mounting systems, supporting residential, commercial, and utility-scale solar projects.

How do solar power factories ensure product quality?

They use automated testing, cleanrooms, and standards like IEC 61215 to guarantee efficiency and durability.

Why are solar power factories important for sustainability?

They produce clean energy technologies, reducing reliance on fossil fuels and lowering carbon emissions.

What are the main challenges for solar power factories?

Supply chain issues, energy-intensive processes, and recycling needs are key hurdles, addressed through innovation.

How are solar power factories evolving?

They’re adopting automation, advanced materials, and sustainable practices, with new facilities expanding globally.

Conclusion

Solar power factories are the backbone of the renewable energy revolution, producing the components that power homes, businesses, and entire regions with clean electricity. From polysilicon to complete PV systems, these facilities drive sustainability, innovation, and economic growth. As global demand for solar energy grows, solar power factories are scaling up, adopting advanced technologies, and creating a brighter, greener future. For cutting-edge solar products from leading manufacturers, visit Power Solution.